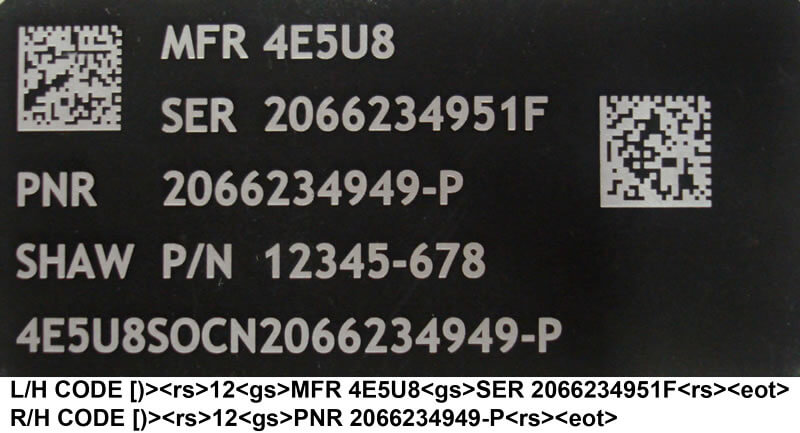

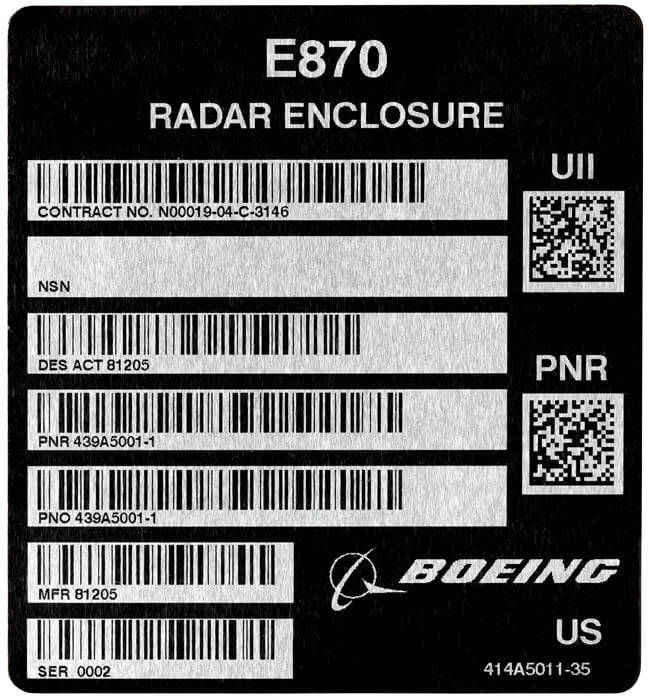

MIL STD 130 Construct 1 IUID Labels

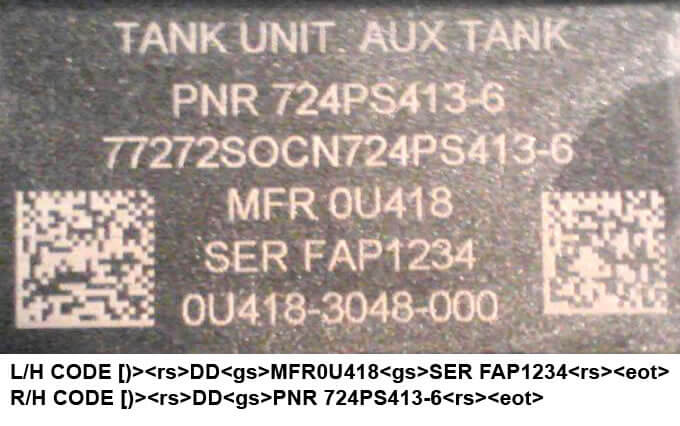

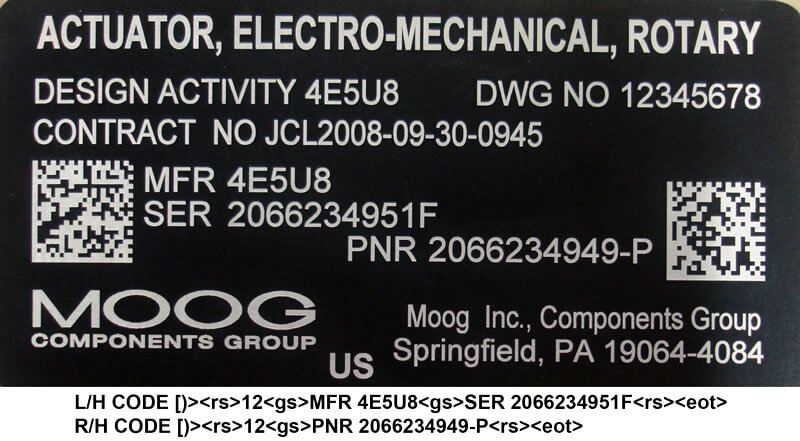

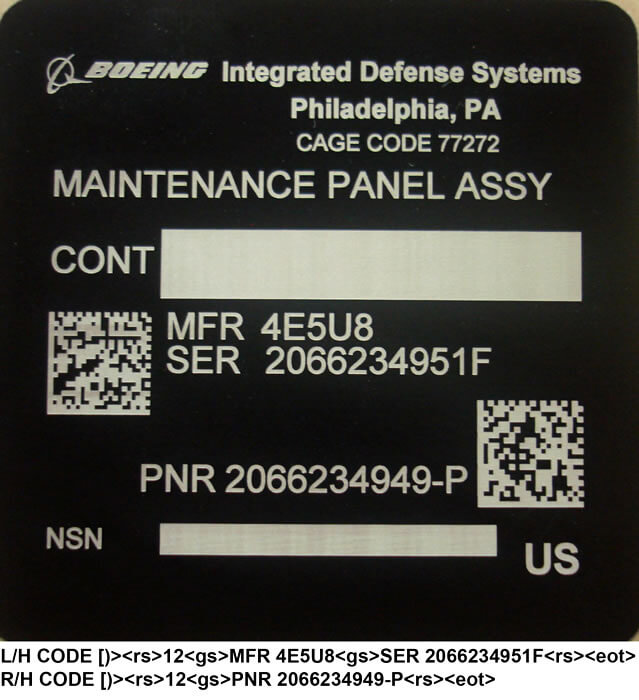

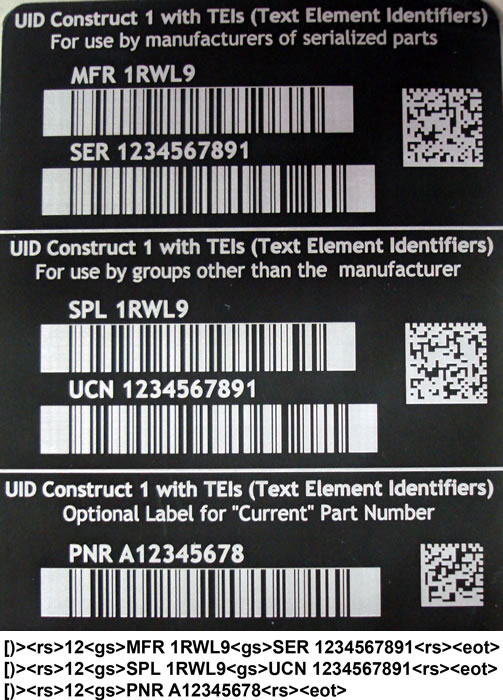

A Construct 1 layout includes the CAGE code and the serial number in either one or two Data Matrices. Essentially, items are serialized at the enterprise level.

Following are labels in a variety of materials and layouts that meet Military Standard 130 Construct 1 requirements. There are many other layout options. Although most of these have a black background with white text, you may choose any Pantone® color for your label or nameplate text and background. Contact us if you have questions or would like guidance. Visit IUID Construct 2 to learn more about another MIL-STD-130 label, nameplate and tag data layout option.

Click a photo to see a larger version of the label plus details about how the data is laid out on the label.

Contact us today to order and to talk with a government compliance label and nameplate specialist.